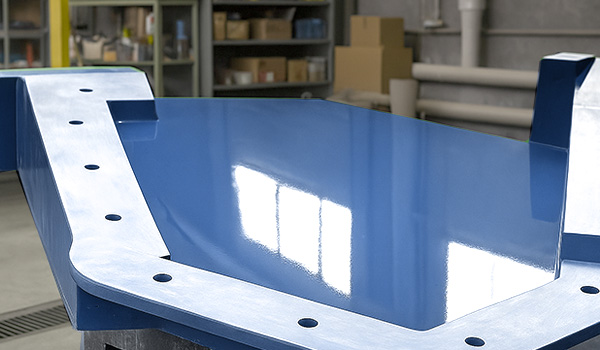

Maximum hardness and resistance to styrene: the ideal gelcoat for long-lasting molds

Poly3 mold gelcoat is formulated on a vinyl ester resin base, where high chemical resistance is required, and an isophthalic resin base when maximized performance is required in molding applications. Designed to resist the chemical aggression of styrene, it offers:

- excellent surface hardness

- high chemical resistance

- long life over time even under thermal and mechanical stress

Thanks to its advanced formulation, the gelcoat for molds (especially the vinyl ester-based one) maintains its surface integrity even after numerous molding cycles, reducing maintenance times and optimizing production efficiency.

Applications of gelcoat for molds:

- Surface coating of the master mold

The gelcoat is applied to the model to create a composite mold. It guarantees a smooth and defined finish, faithfully replicating the surface of the model. - Release surface creation

A good gelcoat for molds forms a surface compatible with release waxes, improving the release of the parts and protecting the structure of the mold. - Protection from chemical agents and abrasion

Vinyl ester mold gelcoats resist solvents, aggressive resins and wear due to repeated production of parts. - Anti-osmosis barrier (in humid environments)

Especially in nautical environments, the gelcoat protects the mold from humidity, avoiding osmosis that can degrade the composite. - Aesthetic finish of the mold

A correctly applied gelcoat guarantees a mirrored surface to the mold, which is reflected in the pieces produced.