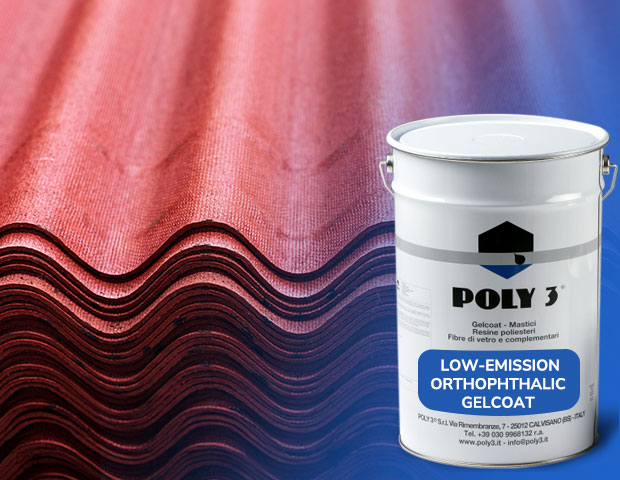

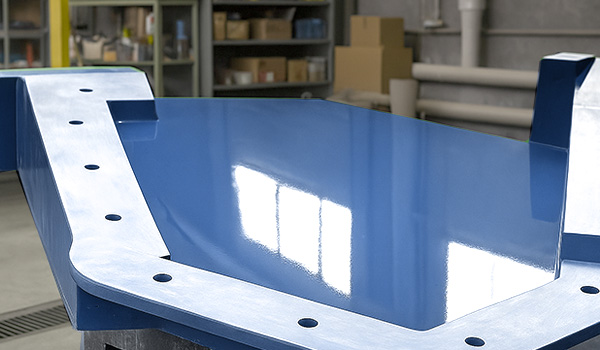

Low-styrene gelcoat for safer working environments

The low-emission Poly3 gelcoat meets the needs of environmental sustainability and health protection in industrial contexts.

In fact, the special formulation of this gelcoat shows a reduced content of styrene, the main volatile organic compound (VOC) present in traditional thermosetting products. This feature makes it particularly suitable for use in industrial environments and allows operators to work more safely and comfortably, helping to reduce emissions into the atmosphere.

The low styrene emission has a twofold advantage:

- significantly reduces fumes and odors released during application, improving the quality of the air in the workplace;

- favorizes compliance with increasingly stringent environmental regulations regarding industrial emissions.

Despite its low-impact formulation, the product maintains high performance in terms of adhesion, mechanical resistance and surface finish, guaranteeing the quality required in professional production processes.

Main areas of application:

- Industrial and manufacturing sector: production of fiberglass components for systems, machinery and support structures.

- Construction Industrial: cladding and paneling for prefabricated buildings, roofs, and technical structures.

- Components for transport and special vehicles: internal and external surfaces requiring subsequent finishing or painting.

- Technical furniture: where emission control is particularly critical.

Thanks to its eco-friendly profile and reliable performance, low-emission orthophthalic gelcoat is an ideal choice for companies that want to optimize work quality, personnel safety, and environmental sustainability without technical compromises.

Choosing Poly3 means adopting a solution that combines efficiency, responsibility, and the right balance between performance and affordability.

Related application sectors

Automotive and transportation

Agriculture and Food sectors

Industry

Building industry and architecture

Furniture and design